Polypropylene Woven: The Secret Behind Durable Bulk Bags & Sustainable Packaging

Polypropylene Woven: The Unsung Hero of Modern Packaging

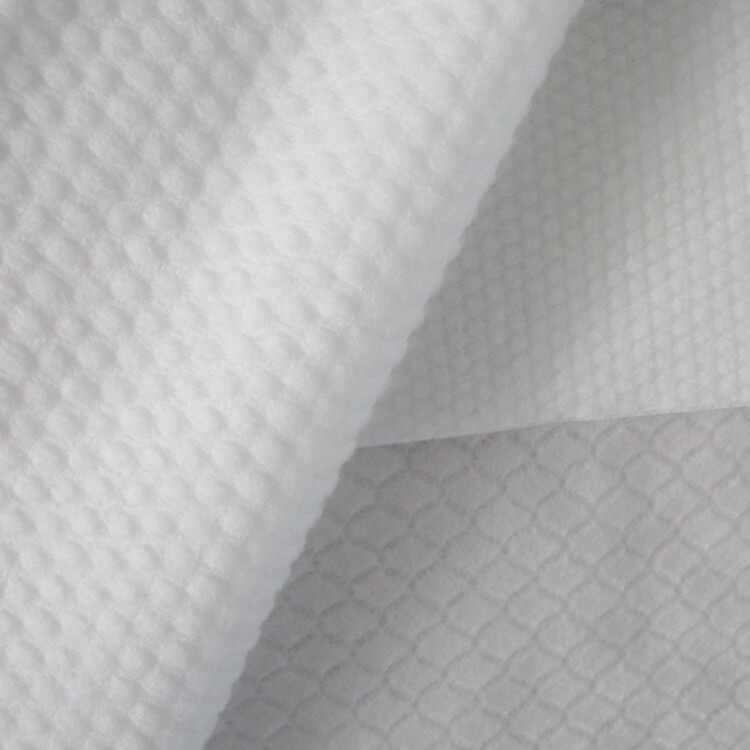

You’ve probably carried groceries in polypropylene woven bags without even realizing it. That sturdy, slightly crinkly fabric that holds 20kg of rice without breaking a sweat? That’s polypropylene woven – and it’s quietly revolutionizing how we package everything from building materials to humanitarian aid. After visiting factories where this material gets stress-tested to its limits, I’m convinced it’s one of manufacturing’s most underrated innovations.

What Exactly IS Polypropylene Woven?

Let’s break this down without the engineering jargon:

Polypropylene = A thermoplastic polymer (think food-safe plastic)

Woven = Threads interlaced like traditional fabric

Combine them and you get a material that’s:

- Stronger than steel by weight (pound for pound)

- Resistant to moisture and most chemicals

- Flexible yet durable enough to survive international shipping

The easiest way to picture it: imagine a super-tough version of the fabric in your reusable shopping bag, but engineered for industrial heavy lifting.

How It’s Made: From Plastic Pellets to Tough Fabric

The process is surprisingly elegant:

- Extrusion: Plastic pellets melted and pressed into flat tapes

- Stretching: Tapes oriented for maximum strength

- Weaving: Looms interlace tapes into fabric (like making denim)

- Lamination: Optional coating for waterproofing

At facilities like Zhejiang Xinrui New Materials, this happens in continuous, automated lines that can produce a football field’s worth of fabric every hour.

Why Businesses Choose Polypropylene Woven

1. Strength That Surprises Everyone

A single layer can typically handle:

- 500-1000 Newtons/5cm tensile strength

- 15-25kg load capacity in standard totes

- Extreme stacking in warehouses

2. Natural Water Resistance

Unlike cotton or jute:

- Repels moisture naturally

- Won’t rot or mildew

- Maintains strength when damp

3. Eco-Credentials That Actually Make Sense

- Recyclable at end of life

- Reusable hundreds of times

- Lightweight = lower shipping emissions

- Often made with recycled content

4. Customization Superpowers

Businesses love that they can:

- Print vibrant brand logos directly on the fabric

- Choose from various weights and weaves

- Select different coating options

- Customize sizes from small pouches to giant bulk bags

Real-World Applications You See Daily

Food & Agriculture:

- 25kg grain and flour bags

- Produce sacks at grocery stores

- Animal feed packaging

Construction & Industry:

- Sand and cement bags

- Geotextiles for soil stabilization

- Protective wraps for building materials

Retail & Shopping:

- Reusable grocery totes

- Promotional giveaway bags

- Fashion retailer shopping bags

How It Compares to Other Materials

| Material | Tensile Strength | Water Resistance | Cost |

|---|---|---|---|

| PP Woven | Excellent | Excellent | Low |

| Cotton | Good | Poor | Medium |

| Jute | Fair | Poor | Low |

| Non-Woven PP | Fair | Good | Very Low |

| Paper | Poor | Very Poor | Low |

The Sustainability Question Answered

“Yes, it’s plastic, but…” context matters:

- 1 PP woven bag replaces 500+ disposable plastic bags

- Recyclable through many grocery store programs

- Lightweight nature reduces transportation emissions

- Durability means fewer replacements

*Zhejiang Xinrui’s rPP (recycled polypropylene) options contain up to 80% post-consumer waste while maintaining the same strength standards.*

Common Misconceptions Debunked

Myth: “It feels cheap and flimsy”

Truth: High-quality PP woven has a soft, linen-like hand feel and exceptional durability.

Myth: “It’s not breathable”

Truth: The woven structure allows air circulation while blocking moisture.

Myth: “All PP woven is the same quality”

Truth: Varies dramatically based on:

- Tape thickness and orientation

- Weave density (number of threads per inch)

- Coating quality (if applicable)

Why Manufacturers Like Zhejiang Xinrui Matter

Having visited their production facilities, the difference lies in:

- Precision control of tape thickness and tension

- Quality raw materials (food-grade versus industrial-grade PP)

- Advanced looms that maintain consistent weave density

- R&D focus on developing stronger, lighter variations

The Future of Polypropylene Woven

Innovations we’re seeing:

- UV-resistant versions for multi-year outdoor use

- Anti-static weaves for electronic components

- Lighter weights with same strength (down to 60gsm)

- Bio-based polypropylene from renewable sources

The Bottom Line

Polypropylene woven isn’t just “plastic fabric” – it’s a sophisticated material solving real problems in packaging, agriculture, and construction. Its combination of strength, sustainability, and customizability makes it the go-to choice for businesses that need reliable performance without environmental guilt.

Considering PP woven for your products?