What is Spunlace Nonwoven Fabric? Types, Uses & Key Advantages

Not All Nonwovens Are Created Equal

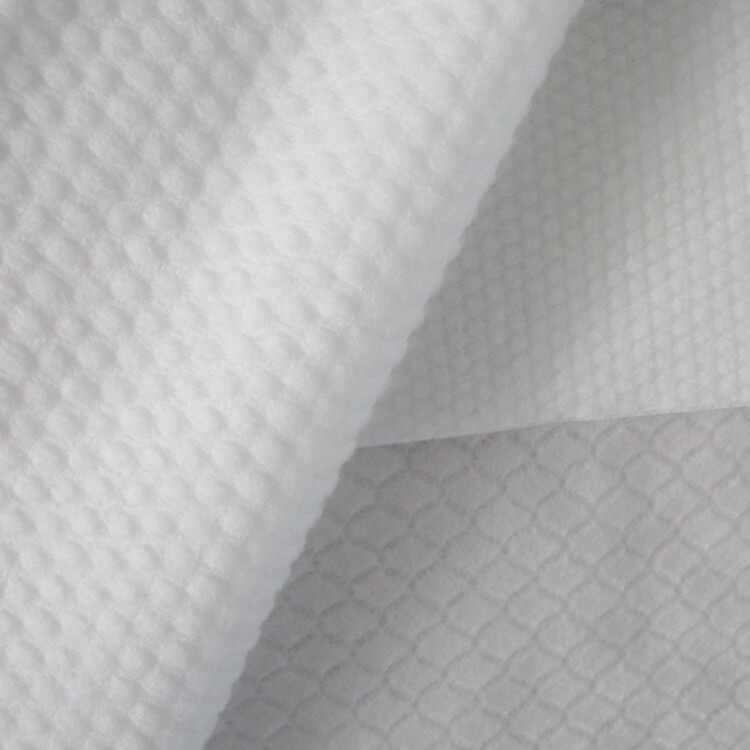

Walk down any supermarket aisle and you’ll touch it – that surprisingly soft yet durable sheet in your makeup remover wipes or that premium surgical gown. That’s spunlace nonwoven fabric, and it feels nothing like the scratchy, paper-like nonwovens you might imagine. The secret isn’t glue or heat; it’s millions of high-pressure water jets.

Let’s break down how this fabric is made, why its texture is a game-changer, and how to choose between its different types for your project.

How It’s Made: The Power of Water Entanglement

Forget spinning yarn. The process, called hydroentanglement, is more like giving fibers a high-pressure water massage.

- Fiber Web Formation: First, carded fibers (like cotton, polyester, or viscose) are laid into a loose, uniform web.

- The Water Jet Treatment: This web then passes over a series of fine, high-pressure water jets (think 60-80 bar pressure). These jets are like precision needles of water.

- Tangling = Strength: The force of the water pushes and tangles the fibers around each other, knotting them into a strong, integrated web. The more jets (or “looms”), the denser and stronger the fabric.

- Drying & Finishing: The fabric is dried and can be treated for specific properties (like anti-bacterial finishes).

The result? A fabric with the drape and softness of a textile but the cost-effective production of a nonwoven. No chemical binders mean it’s often purer and more skin-friendly.

The Two Main Types You’ll Encounter

Choosing the right type depends on whether you prioritize natural feel or performance strength.

1. Natural Fiber Spunlace

This is the go-to for high-end hygiene and skincare.

- Common Blends: 100% Cotton, Cotton-Viscose, Bamboo-Viscose.

- The Feel: Exceptionally soft, highly absorbent, and breathable. It has a natural, cloth-like hand feel.

- Key Uses:

- Premium facial wipes and cosmetic applicators

- Biodegradable dry wipes

- Lightweight medical dressings and wound care

- The Trade-off: Generally less strong when wet (lower wet tensile strength) compared to synthetic blends.

2. Synthetic & Blended Spunlace

This is the workhorse for durability and specific technical functions.

- Common Blends: Polyester (PET), Polypropylene (PP), or Polyester-Viscose mixes.

- The Feel: Softer than other nonwovens, but with a more performance-oriented, sometimes slightly crisper hand. Excellent strength.

- Key Uses:

- Heavy-duty industrial wipes (for solvents, oils)

- Strong, reusable cleaning cloths

- Synthetic leather base, composite materials

- Durable medical drapes and gowns

- The Advantage: Superior wet strength, better abrasion resistance, and often more cost-effective for high-volume, performance-driven applications.

Why Choose Spunlace? The Real-World Advantages

When you specify spunlace nonwoven fabric, you’re not just picking a material; you’re choosing a set of benefits:

- No Chemical Binders: A major plus for sensitive skin, baby products, and eco-claims.

- Lint-Free: Those high-pressure water jets lock fibers in place, so they don’t shed. Critical for electronics wipes and optical lenses.

- Highly Customizable: You can engineer everything: weight (from 30 to 130 gsm), softness, strength, and absorbency by playing with the fiber mix and water pressure.

- Excellent Drape and Conformability: It wraps and molds better than stiff, thermally-bonded nonwovens, making it ideal for garments and precise wiping.

Matching the Fabric to Your Product

Still unsure which type to explore? Here’s a simple rule of thumb:

- If your primary concern is softness, skin contact, and a natural feel (e.g., luxury cosmetics, baby wipes), start with natural fiber blends.

- If you need strength, durability, and resistance to chemicals or repeated washing (e.g., industrial wipes, reusable products), focus on synthetic or synthetic-blend spunlace.

The best move is to request swatch cards and technical data sheets from your supplier. Feel the difference, test the strength, and see which spunlace nonwoven fabric aligns with your product’s story and function. It’s the material that quietly bridges the gap between disposable convenience and textile-like quality.